This was our entry to the Cornell MAE427 Fall 2000 truck competition. The project was offered by Prof. CHK Williamson as an alternative to doing a short lab report for our third and final fluid mechanics experiment. Needless to say, everyone opted for the competition.

The goal of the competition was to design and build a truck that would win a race down a standard pine wood derby track. The trucks run down a ramp, and then race over several meters of flat track to the finish line, where a nifty array of 6 photoluminescience sensors indicate which of the six trucks finished first. So the design objectives favored aerodynamic trucks that took maximum advantage of the gravitational potential energy from the ramp.

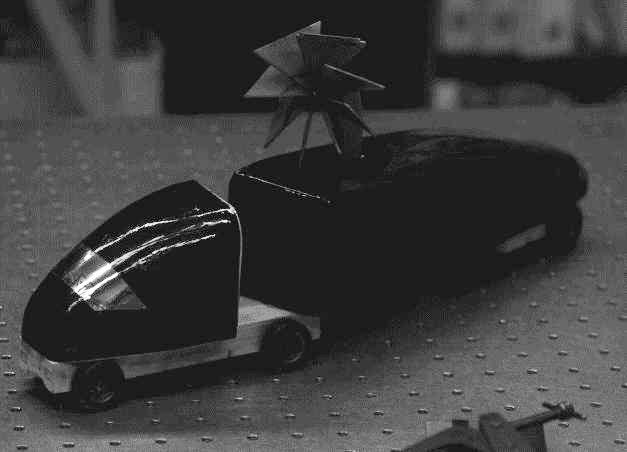

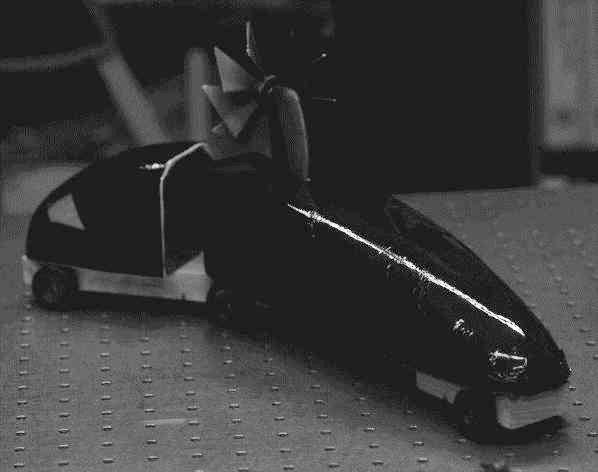

Our rig, the "Heir Apparent", sports a free-spinning pinwheel on top to meet frontal profile requirements (there were no cargo volume requirements for some reason). The theory is once the pinwheel gets spinning, incoming air doesn't see the pinwheel blades in profile, but rather edge-on, thus reducing pressure drag.

We probably could have used pinwheels for the cab and trailer too, but we were pressed for time. We just quickly molded a 3D airfoil shape inspired by, but based on no particular NACA airfoil. The body was covered with heat-shrink sheet plastic commonly used to build model airplanes. This gave it low skin friction plus a nice shiny finish.

The chassis of the car needed to stay pretty much stock, with the articulating joint. We just tried to minimize the number of wheels we had to reduce friction, and practiced applying the right amount graphite dust (you've heard of "liquid" ball bearings, this stuff is literally powdered ball bearings on a microscopic scale).

To maximize our gravitational potential energy on the ramp, we glued lead weights as far back as possible in the trailer. We added as much weight as we could up to the weight limit. We probably could have hollowed out the cab and trailer to move more weight to the rear, maybe next time.

![[Front View]](Buck1.jpg)

One last cheat - wooden dowel rods would rotate down to launch all six contestants simultaneously. We noticed that by cutting a notch on the front underside of the truck, the truck could inch forward slightly while these dowels were rotating down, giving it a very slight advantage.

We did pretty well... the truck made it to the semifinals out of roughly 50 entries. Since the pinwheel was octagonal in shape, the corners would slightly violate width restrictions when it spun. Surely enough, during the semifinals run, the pinwheel struck an adjacent truck and stopped spinning a few times during the races, which turned the pinwheel into a giant airbrake for a few crucial moments. The 6 finalists were pretty close to each other in race times, meaning they must have been pretty close to optimal. So the fact that our truck made it to the semifinals meant that we were close to the optimal time considering the relatively little amount of work and refinement we put into our vehicle.